Automation of repetitive tasks is a currently straightforward strategy of companies’ infrastructure development. Typical approach to separate human workers from the machine and let the robots execute tedious activities is seen in various industries. Most of the manufacturers are keen on automating production, so long as it can be done cost-effectively [1].

Robots reduce costs…

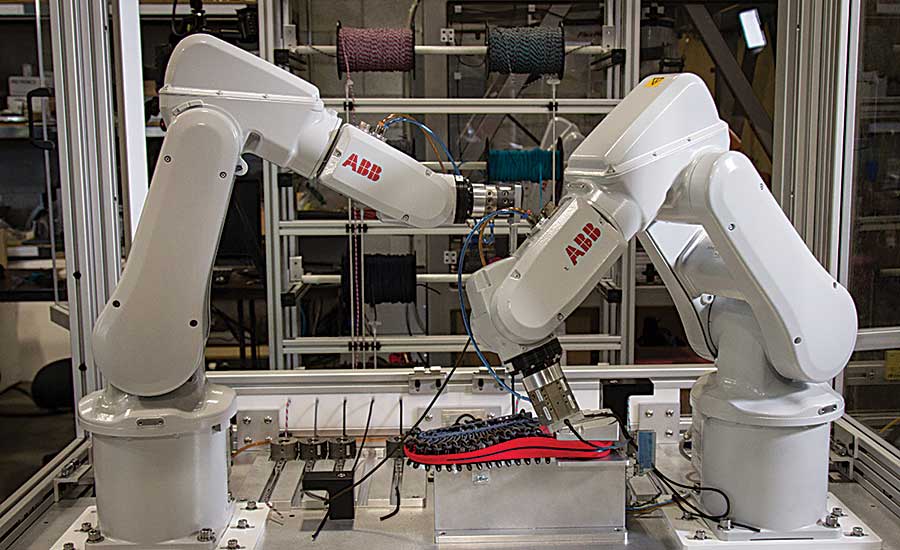

One of the example of such examples of robots application is shoes production process in KEEN Inc. – US based company that makes outdoor and lifestyle footwear. It was founded in 2003, and its shoes are sold in the United States and worldwide. According to Rory Fuerst Jr., director of innovation at KEEN, the most important benefit or automation is the fact that robots are processing the shoes’ interlocking cords with the sole with a speed twice as fast as when done manually reducing favorably production costs. So far, ABB Robotics supplied solutions for many production lines and tasks and declares to sold more than 250,000 robots worldwide.

Potential cost reduction is indisputable benefit of the automation. Robot manufacturers’ sales track record seems to prove their attractiveness and market acceptance. With cost reduction improvement, it is possible to keep the production facilities at countries close to the clients’ and remove some of the capacities that are usually placed far away in developing countries. Automation enables European and American producers to be still price competitive and avoid potential accusations of use of children workers or inhuman working conditions at plants located in developing countries.

Automation is a challenge…

However, automation comes with the limits regarding the process versatility and flexibility. Recently Adidas has announced to end the robotic shoe production in Germany [2]. It had originally the intention to use the automated plants to produce footwear more quickly in locations closer to the key markets. Robots in Germany were supposed to be alternative to manufacturing hubs in Asia, where the labor and overhead are cheaper. Now, the company plans to move the so-called Speedfactory to the Asia, where the ‘know-how and suppliers are located”. However, this was not the only and main reason for such strategic decision. The robotic factories were shown to produce a limited number of models [3]. Any change of the shoe design requires time consuming and costly machine adaptation. The robotic factory seems to be a powerful tool, but difficult to quickly reconfigure or repurpose, since it takes specialty knowledge to set up racks of robotic arms, computer vision systems, and so on. Robotics manufacturers are making advances in this field, but for now it is still a bigger challenge comparing to training a human worker to use standard tools on a different pattern [4].

Manufacturing landscape will change…

In effect, investors should carefully analyze potential of using robotic automation in manufacturing. Current experts, as Kai-Fu Lee, expects that artificial intelligence will automate and potentially eliminate 40 percent of jobs within 15 years [5]. Some people claims, that it would requires decades until robots would be so versatile to be easy implemented in various applications. Assuming the increasing popularity of robot automation and basing on the current level of technology maturity, we can suspect that some of the human workers would be replace in near future, or as Toyota Production System is expecting – to be separate from the machine, and it would not happen fully. For sure, there will be a need for people maintaining the automated system working properly – especially those with high robotic technology skills since the systems become more sophisticated. Moreover, new job roles would become more popular in the market such as automation specialists or automation process engineers, who will be responsibile for robotic process flow. In general, the transition to the more automated technology requires the change in workers skills more oriented on Artificial Intelligence and robotics.

View of the future manufacturing…

The MAPI Foundation (center for research on the economic impact of manufacturing) has published report on AI in production, which claims that introduction of AI into the manufacturing value chain will create new hybrid roles, where humans enable machines, and AI augments human capabilities [6]. In their second study, MAPI has shown that jobs in the manufacturing, retail, telemarketing, and data entry space are most likely to shrink due to AI expansion, yet most respondents of their research said they are not afraid that AI/bots will replace their own jobs within the next 10 years [7]. Anyway, current research and technology transfer efforts prove that job market will witness the urgent and increasing need for properly trained persons and the relevant actions should be taken by the industry to address this demand in upcoming years.

[1] https://www.assemblymag.com/articles/93672-shoe-manufacturer-automates-production-in-unique-way

[3] https://qz.com/1746152/adidas-is-shutting-down-its-speedfactories-in-germany-and-the-us/

[4] https://techcrunch.com/2019/11/11/adidas-backpedals-on-robotic-factories/

[6] https://mapifoundation.org/manufacturing-evolution

[7] https://www.roboticsbusinessreview.com/ai/new-research-shows-how-ai-will-impact-the-workforce/